The shift toward more expansive forms of digital production within the design and construction industry affords opportunities of not only reconfiguring the relationships between the key players, but also incorporating industry sectors not typically associated with building construction. At the core of this shift is the integration of communication through various forms of digital networks, CNC fabrication being just one among many, with the ambition of developing a comprehensive, well organized, easily accessible, and parametrically adaptable body of information that coordinates the process from design through a building’s lifecycle. This is the broader context for the goals of the Avery Digital Fabrication Lab.

Statement on Digital Primitive

What distinguishes CNC technologies for architecture is the opportunity it affords to reposition design strategically within fabrication and construction processes such that what architects actually produce—drawings—shifts from loose representations of buildings to highly precise sets of instructions that are coordinated and integrated into a full description of a building. At a more modest level within this comprehensive organizational picture, CNC has also influenced design methodologies as architects begin to respond more directly to the conditions of digital production as a means for both pragmatic concerns like cost and efficiency and more conceptual potentials like variability and customization. These are the topics of research and experimentation for the lab.

Project 1: AMPHORAE

Location: COLUMBIA UNIVERSITY

Date: SPRING 2007 / FALL 2008

Client: COLUMBIA UNIVERSITY, LAFARGE

Digital tools:

3-D MODELING, CNC FABRICATION

Credits: Design/ fabrication / Implementation

MARK BEARAK, DORA KELLE, ADAM MERCIER, PHILLIP ANZALONE

Description

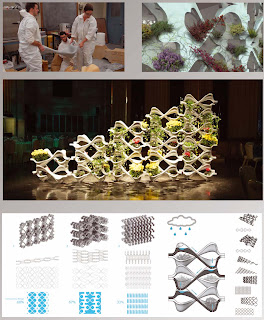

Amphorae is a collection of various objects with differing sizes and functions ranging from small bricks to full pieces of furniture, which are tied together functionally and aesthetically. Our elements range in size and level of detailing based on function. We created a system of ecologically sensitive concrete elements that can be used for the collection, filtration and redistribution of water. These units not only hold water, but they also have smaller pockets with space to grow various forms of plant life that are fed by the individual cisterns.

The project is meant to be far more than simply a structural wall; it is a vertical garden that can be reconfigured and installed anywhere.

The Amphorae elements are constructed from Ductal concrete. Our mixture is composed of recycled sand and reconstituted fly ash as a bonding agent. This mixture reduces carbon emissions by more than 30% when compared to standard concrete. The project goes beyond representation; from concept through execution decisions were made with the environment in mind.

Project 2: FRAMING SPACE

Location: AIA NEW YORK CENTER FOR ART AND ARCHITECTURE

Date: JANUARY 2009

Client: AIA NEW YORK CENTER FOR ART AND ARCHITECTURE

Digital tools:

3-D MODELING, CNC FABRICATION

Credits:

Design/ fabrication / Implementation

PHILLIP ANZALONE AND STEPHANIE BAYARD OF ATELIER ARCHITECTURE 64, GSAPP/PRATT INSTITUTE STUDENT TEAM

Description:

Framing Space was an installation designed and constructed for the AIA-NY Center for Architecture “Make It Work: Engineering Possibilities exhibition. The installation was a collaborative between two Architecture Schools (GSAPP and Pratt), an architecture firm (Atelier Architecture 64) and a number of sponsors with a goal for education and demonstration of structural and design possibilities through the use of new materials, processes and design techniques. The Framing Space exhibition piece seeks to explore the relationship between craft, in its simultaneous traditional and constructive connotations, and contemporary methods of architectural construction. This study is done through the filter of material qualities, decoration, assembly details and other technical constructive means. The resulting installation evokes and engages with the human through optical, textural and conceptual qualities to bring to the surface the juxtaposition and potentials inherent in the joining of the old and the new. The Trusset Structural System used in this construction was invented by Phillip Anzalone and Cory Clarke.

Project 3: SLIDE LIBRARY

Location: DEPARTMENT OF ART AND ARCHAEOLOGY

Date: 2005

Client: COLUMBIA UNIVERSITY

Digital tools:

3-D MODELING, CNC FABRICATION

Credits:

Design/ fabrication / Implementation

MARBLE FAIRBANKS /COLUMBIA GSAPP STUDENT TEAM

Description

This project was completed both as a prototype research project to test computerized fabrication techniques, and to fulfill the immediate program needs of the client as the first phase of a longer-term master plan. The design consists of four walls defining the space of the slide library and lit by the skylight above.

The east wall is made up of 435 sandwiched layers of 1” thick ultralight (lightweight mdf). Occasional viewing portals are formed by carved layers on opposite sides of the wall where two 1/2” thick glass panels are inserted. The middle of the east wall curves into the space to capture light in the hall outside from a skylight above. The edges of the glass panels refract and glow from natural light. The north, south and west walls are patterned with 1/4” perforated lines outlining the actual tooling paths for each of the layers of the east wall – these lines are illuminated by the light of the skylight in the slide library. As part of the rigor to digitally draw, fabricate and manage the entire project, every component of the design was milled regardless of its complexity to enable thewalls to be assembled like furniture.

No comments:

Post a Comment